Special Machines: Flow Testing Solutions

Explore the Special Machines Section

Special Machines and custom built equipment provide the best method for solving those bespoke requirements which include assembly, handling and testing disciplines.

Explore this section to find out more about the how TQC can help you with your special machines and custom, bespoke machine requirements

- Special Machines

- Test Machine Equipment

- Plastic Processing

- Feasibility Studies / Proof of Principal / Prototyping

- Case Studies

- Turbocharger Testing

- Clutch Testing

- Plastic Bumper Punch Machines

- Plastic Bumper Assembly and Checking Fixtures

- Plastic Bumper Painting & Polishing Fixtures

- Rear Bumper Handling, Assembly and Pressing

- Front Bumper Assembly and Pressing

- Mechanical Handling - Dynamic Buffer Conveyor

- Platen Based Flow Testing of Turbocharger Housings

- Gas Supply and Monitoring System

The general concept of flow testing and flow measurement is to apply a pressure to a test medium through a flow path within a test part and measure the resulting flow.

Flow testing is used in many industry sectors and on a number of different parts including many automotive castings and pipework runs and parts such a valves.

Flow testing can be used for the following applications –

- Blockage testing to ensure that a defined path is present and not blocked

- Function testing of valves and other actuators to ensure correct opening and closing

- An alternative method of leak testing parts by measuring the flow with parts

- Turbocharger testing

TQC provide flow test and measurement equipment and a flow testing service. Test mediums used include air, water and hydraulic oil, test instrumentation can be via a standard equipment or a bespoke engineering solution. Flow testing can be performed on dedicated equipment or be a station within a system.

Platen based handling system for automatic transfer of turbocharger housing casting to a flow testing station, checking the flow readings and then passing or failing each part as necessary. Fur further details view our Case Study for this machine

Pneumatic valve testing within interchangeable tooling. This system also did function testing and leak testing of the component.

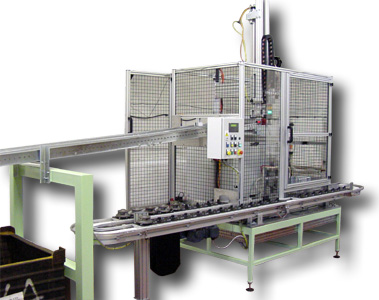

The photograph below shows a typical self-contained production line test unit.

The model shown here is for the flow and pressure testing of refridgerant compressors. Such units feature automatic pressure control, data logging and results printout, and are fitted with quick connectors and sliding guards for ease of use.

To find out more about how we can help you with your special machine and flow testing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561