Leak Testing: Contract Leak Testing Services for Small Batch Production Parts

Explore the Leak Testing Section

Leak Testing is used to ensure quality, tested and proven parts are supplied into the market. The use of leak testing equipment eliminates failures in the field.

Explore this section to find out more about the how TQC can help you with your leak testing requirements

- Overview

- Air Decay

- Helium

- Other Test Methods

- Leak Testing Services

- Standard Equipment

- Case Studies

- Automotive Brake Leak and Flow Testing

- Automotive Bedplate Leak Test Machine

- Battery Tray Leak Test Machine

- Chilled Beam Leak Test

- Flexible Leak Test Facility

- Fuel Tank Leak Testing

- Helium Leak Test Bench

- Helium Leak Testing of Automotive Fuel Pipes

- High Pressure Audit Leak Testing System with Datalogging

- High Speed Leak Testing of Pipe Fittings using Air and Helium

- High Speed Leak Testing of Plastic Vial for the Medical Industry

- Leak Test Facility for Water Valves

- Leak Test Cell with Robotic Handling

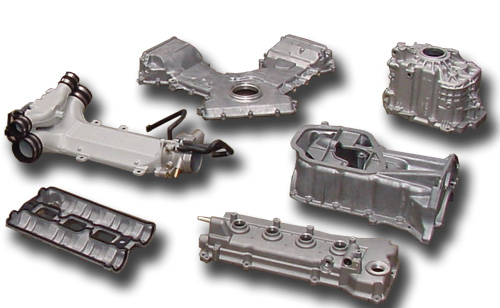

- Casting Leak Testing of Engine Blocks

- Medical Filter Leak Test Machine

- Medical Showerhead Leak Test Machine

- Plastic Fuel Rail Leak and Burst Test Machine

- Plastic Sump Pipe Leak Test and Assembly

- Small Medical Device Leak Test Machine

- Twin Station Leak Test Machine for Oils Sumps

- V6 Cylinder Head Leak Test Machine

- V6 Engine Leak Test Machine

- V8 Cylinder Head Leak Test Machine

- V8 Engine Block Leak Test Machine

- Valve Block Leak Test Machine

- Vauxhall Leak Test Machine

- Weapon Leak Test Machine

Do you need a part leak testing?

Contact TQC to perform leak testing services on parts without the need to capital invest in your own leak testing system.

TQC offers leak test services on a contracted basis when investment in instrumentation is not a feasible spend. We work with clients to develop test specifications and carry out leak testing at our site in Nottingham on small batches of parts, on prototypes and where the client may already have leak testing machines in-house that cannot test to specific standards that have been defined.

Typically our Clients using our leak test services have:

- A requirement to leak test prototypes as parts of the R&D process.

- A prototype sealing system they are developing, requiring leak testing to be cared out as part of the development.

- Produced a small batch of parts that will not go into general production and so need one-off leak testing carrying out (Pre production parts)

- A requirement to leak test regular batches of small parts but do not want to commit to the expenditure of investing in their own leak test equipment.

- A requirement to leak test a particular product beyond the range or standards of in-house leak test equipment.

At TQC, we are specialists in developing bespoke leak testing solutions for a wide range of industries. Our highly experienced in-house engineering staff can develop and write test specifications and procedures to cover any critical testing requirement.

TQC’s standard equipment includes a full set of calibrated, traceable leak testing instrumentation (NIST, NAMAS) available for leak testing small quantity batches of parts.

The leak testing equipment covers an extensive range of pressures. Typically, leaks of 10 mm3.sec-1 can be detected using air decay testing and leaks down to 1x10-8 mbar.l.sec can be traced by using helium leak testing.

Leak test pressures of up to 1095 bar can be developed on a bespoke service basis. Please enquire for a feasibility study on this kind of leak test service that are normally executed via helium tracer gas testing or differential pressure air decay testing, helium sniffing and spraying.

Examples of leak test service use cases are:

Examples of leak test service use cases are:

- Helium leak testing of fabrications

- Testing of high performance racing brakes, engine parts and under bonnet

- Medical device testing of prototypes

- Development of sealing for bottle closures

- Pressure and leak testing of machined parts

- Exhaust pipe leak testing in singular or small batches for specialist vintage cars

TQC also has experience in sealing techniques and sealing materials so can provide technical guidance on this as part of the service.

We have a number of overpressure and vacuum test chambers available to users of our leak testing services and a range of pressurising and vacuum generation equipment available.

To find out more about how we can help you with your leak testing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines experience to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561