Assembly Automation: Checking jigs and assembly fixtures - Overview

Explore the Assembly Automation Section

Automatic assembly machines and automation system solutions provide the best method for reducing labour costs, increasing output and eliminating manual handling concerns.

Explore this section to find out more about the how TQC can help you with your factory assembly automation processes

- Assembly Automation

- Pallet Transfer Systems

- Rotary Systems

- Assembly Benches

- Robotics and Handling

- Checking Jigs & Assembly Fixtures

- Case Studies

- Casting Multi-Position Screwdriving & Marking System

- Co-operating Robots

- Pallet Assembly System for Automotive Glovebox Latch

- Pallet Assembly System for Metal Pressed Parts

- Laser Marking & Verification System

- Lead Pot Robotic Handling System

- Automotive Plug Feed & Check System

- Poka Yoke Assembly Bench for Automotive Latch

- Bearing Automatic Heat, Press & Assembly System

- Hot Insert, Cold Insert & Seal Assembly/Check System

- Robotic Handling & Leak Test Cell

- Robotic Weld & Fabrication System

- SCARA Robot cell for Automatic Assembly of a Small Electrical Handset

- Semi-Automatic Assembly System for Automotive Radiators

- Cylinder Head Cover Clean, Assemble and Test Suite

- Automotive Hinge Assembly & Test System

TQC have designed and produced a number of jigs and fixtures for several applications across a number of industry sectors including the automotive, automotive plastics, welding and aerospace industries.

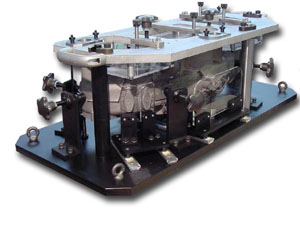

Large aerospace casting checking fixture

The abilities of our in-house jig and tool design facilities enable simple jigs and more complex fixtures to be designed to suit the customers requirements. Laser cut tooling is comonly used as this allows complex shapes to be cut to match customer design information.

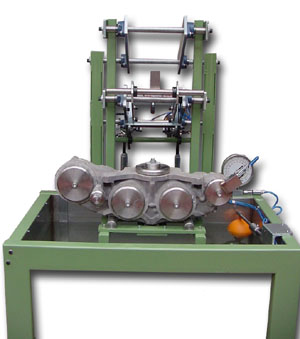

Jigs and fixtures along with specific tooling form a critical element of machinery designed and supplied by TQC, it is this experience which is used to supply standalone jigs and fixtures to our customers when required. The examples of checking jigs and assembly fixtures shown here vary from a large fixture for measuring and checking a casting for the aerospace industry to a small cost effective checking jig to hold an automotive plastic bumper during the manual polishing process.

TQC jigs and assembly fixtures can aid manual operations by aligning parts to reference datums, securing parts so additional functions can be easily carried out or simply allowing easy access to opposite faces. Many jigs and fixtures supplied are more of an intelligent fixture and incorporate poka yoke, an important requirement especially in the automotive industry for ensuring that it is not possible to produce incorrect parts

Typical applications of TQC produced jigs and fixtures:

Checking and Measurement Fixture

- Automotive castings

- Automotive plastic bumpers & grills

- Aircraft castings

- Automotive welding fixtures

- Aircraft structures

- Automotive interior trim

.

Welding Fixture

Plastic Bumper Polishing Fixture

Underwater leak test fixture

To find out more about how we can help you with your jigs and fixture requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561