Assembly Automation Case Studies: Lead pot robotic handling system of radioactive vials

Explore the Assembly Automation Section

Automatic assembly machines and automation system solutions provide the best method for reducing labour costs, increasing output and eliminating manual handling concerns.

Explore this section to find out more about the how TQC can help you with your factory assembly automation processes

- Assembly Automation

- Pallet Transfer Systems

- Rotary Systems

- Assembly Benches

- Robotics and Handling

- Checking Jigs & Assembly Fixtures

- Case Studies

- Casting Multi-Position Screwdriving & Marking System

- Co-operating Robots

- Pallet Assembly System for Automotive Glovebox Latch

- Pallet Assembly System for Metal Pressed Parts

- Laser Marking & Verification System

- Lead Pot Robotic Handling System

- Automotive Plug Feed & Check System

- Poka Yoke Assembly Bench for Automotive Latch

- Bearing Automatic Heat, Press & Assembly System

- Hot Insert, Cold Insert & Seal Assembly/Check System

- Robotic Handling & Leak Test Cell

- Robotic Weld & Fabrication System

- SCARA Robot cell for Automatic Assembly of a Small Electrical Handset

- Semi-Automatic Assembly System for Automotive Radiators

- Cylinder Head Cover Clean, Assemble and Test Suite

- Automotive Hinge Assembly & Test System

Client: Confidential Pharmaceutical Company

Part: Lead Pot containing radioactive material

Machine supplied: Lead Pot Robotic Handling System

Overview: This system was designed and manufactured in order to give the customer the ability to handle an unstable radioactive material safely within their production environment. TQC developed this system alongside the client from the feasibility study stage through to implementation.

Download details of this system as a PDF

Key features:

- Fully Automated Production Facility for the Medical Industry

- GAMP 4 Compliant Project

- Clean Room Environment

- Automated Heavy Lead Pot Handling

- Comms for MIS

- Radioactive Product at Low Temperature

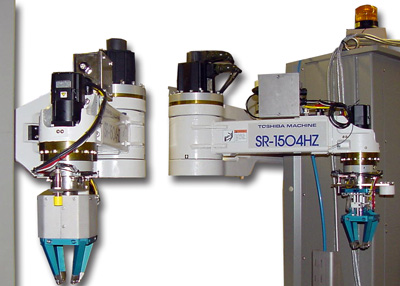

- Toshiba SCARA robotic handling

- Robot Payload 14Kg

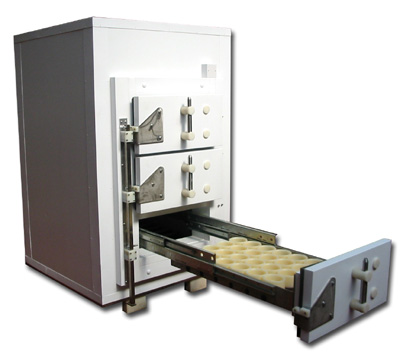

- Product Storage at below –23°C

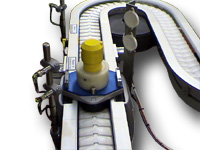

- Flexlink conveyor system

- Touch Screen HMI terminal with Allen Bradley SLC5/04 PLC Control and Controlnet Flex I/O

- Barcode reading & product tracking and colour recognition

The special purpose automatic system was designed and manufactured for the automated handling of lead pots that contained radioactive vials. TQC were involved from feasibility study through process validation exercises and then into the full engineering of the automation system to result in a fully accepted facility.

Lead Pot Robot Handling System detail

The radioactive drug needed to be chilled to below –23°C within a short space of time. Due to the temperature and the radioactivity of the product it was important that during the process the product was away from human contact.

The storage of the product was remote to the production area, which needed TQC to develop a specially designed mobile freezer system. TQC provided full project management facilities integrating robots, conveyor systems, pallet docking stations, mobile freezers, control system etc all within a GAMP 4 project.

The system process involves docking of an empty mobile freezer unit, this is then filled with empty pots. The pots are then chilled to the storage temperature. To fill the chilled pots, the robots open the mobile freezer drawers and sequentially unload each pot and loads it onto a transfer conveyor. After filling a second robot, the system loads a second mobile freezer with the pots. This complete process is carried out to tight timescales to ensure the product is swiftly chilled and the low temperature is maintained.

Details from the fully automated robot system handling radioactive materials

To find out more about how we can help you with your automated assembly systems:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561