Assembly Automation Case Studies: Automotive sump plug feed and checking system

Explore the Assembly Automation Section

Automatic assembly machines and automation system solutions provide the best method for reducing labour costs, increasing output and eliminating manual handling concerns.

Explore this section to find out more about the how TQC can help you with your factory assembly automation processes

- Assembly Automation

- Pallet Transfer Systems

- Rotary Systems

- Assembly Benches

- Robotics and Handling

- Checking Jigs & Assembly Fixtures

- Case Studies

- Casting Multi-Position Screwdriving & Marking System

- Co-operating Robots

- Pallet Assembly System for Automotive Glovebox Latch

- Pallet Assembly System for Metal Pressed Parts

- Laser Marking & Verification System

- Lead Pot Robotic Handling System

- Automotive Plug Feed & Check System

- Poka Yoke Assembly Bench for Automotive Latch

- Bearing Automatic Heat, Press & Assembly System

- Hot Insert, Cold Insert & Seal Assembly/Check System

- Robotic Handling & Leak Test Cell

- Robotic Weld & Fabrication System

- SCARA Robot cell for Automatic Assembly of a Small Electrical Handset

- Semi-Automatic Assembly System for Automotive Radiators

- Cylinder Head Cover Clean, Assemble and Test Suite

- Automotive Hinge Assembly & Test System

Client: Automotive Parts Finishing Group of Companies

Part: Automotive Sump Plug

Machine supplied: Automotive Plug Feed and Checking System

Overview: This system was designed and manufactured in order to give the customer the ability to 100% inspect that a process had been carried out within their production environment. TQC developed this system alongside the client to allow them to automatically feed various sizes of part from bulk and automatically inspect the presence of a sealing bead.

Download details of this system as a PDF

Key features:

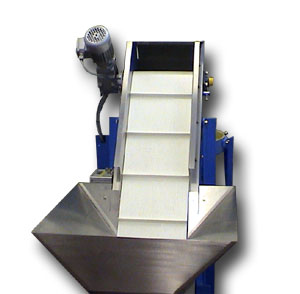

- Elevating Hopper & Vibratory Bowl Feeder

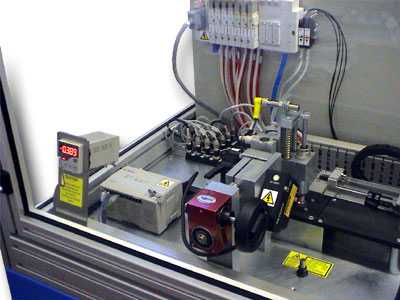

- Laser displacement measurement system

- Walking beam transfer system

- PLC Control

Laser measuring of a sealing bead

on an automotive plug

To meet the demands of 100% checking and inspection requirement that are becoming standard within the automotive industry, TQC designed and manufactured a standalone machine for the automatic feeding and checking of an automotive plug. Utilising an elevating hopper and vibratory bowl feeder to accept bulk product and orientate each plug, a laser measurement system is incorporated to check a feature on the product. The plug is transported through the machine using a walking beam and the part is rotated a full 360 degrees.

The automotive industry based customer required a 100% check to ensure that a continuous bead of thread locking sealant is the correct thickness and continuous round the flange. The system accommodates a single size of stud at any one time, but is adjustable for sizes from M10 to M20, the overall throughput was 20 studs per minute.

Detailed photos - measurement sensor, automated feed system and hopper and inspection overview

To find out more about how we can help you with your automated assembly systems:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561