Assembly Automation: Jigs & Fixtures - Laser cut profiles

Explore the Assembly Automation Section

Automatic assembly machines and automation system solutions provide the best method for reducing labour costs, increasing output and eliminating manual handling concerns.

Explore this section to find out more about the how TQC can help you with your factory assembly automation processes

- Assembly Automation

- Pallet Transfer Systems

- Rotary Systems

- Assembly Benches

- Robotics and Handling

- Checking Jigs & Assembly Fixtures

- Case Studies

- Casting Multi-Position Screwdriving & Marking System

- Co-operating Robots

- Pallet Assembly System for Automotive Glovebox Latch

- Pallet Assembly System for Metal Pressed Parts

- Laser Marking & Verification System

- Lead Pot Robotic Handling System

- Automotive Plug Feed & Check System

- Poka Yoke Assembly Bench for Automotive Latch

- Bearing Automatic Heat, Press & Assembly System

- Hot Insert, Cold Insert & Seal Assembly/Check System

- Robotic Handling & Leak Test Cell

- Robotic Weld & Fabrication System

- SCARA Robot cell for Automatic Assembly of a Small Electrical Handset

- Semi-Automatic Assembly System for Automotive Radiators

- Cylinder Head Cover Clean, Assemble and Test Suite

- Automotive Hinge Assembly & Test System

TQC have designed and produced a number of jigs and fixtures for several applications across a number of industry sectors including the automotive, automotive plastics, welding and aerospace industries, a lot of these fixtures have been manufactured using laser cut profiles.

The abilities and experience of our in-house jig and tool design facilities enable fixtures to be designed around customer parts and customer design information. 3D CAD information can be used in combination with laser cutting to produced laser cut profiles that match the customer's parts.

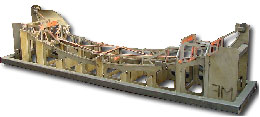

A large number of laser cut profile based fixtures supplied have been for the automotive plastics industries for the handling of plastic bumper during the painting process. As part of the supply, TQC can develop mounting frames for multiple fixtures so that a number of mouldings can be transferred down the paint line. Laser cut fixtures can be CMM checked to ensure the fixture matches the CAD data. To compliment the supply of these fixtures checking or repair fixtures can be supplied, these are also used for manufacturing production volumes of fixtures.

checking fixture for bumper paint fixture

Typical fixture for locating a plastic

bumper during robotic paining

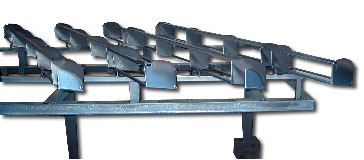

Typical applications of TQC laser cut profiles:

- Front and rear bumpers

- Sills and spoilers

- Vehicle grilles

- Ancillary trim mouldings

examples of where laser cut profiles are used for location tooling

To find out more about how we can help you with your jigs and fixture and laser cut profiling requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561