Assembly Automation: Rotary machines and rotary systems

Explore the Assembly Automation Section

Automatic assembly machines and automation system solutions provide the best method for reducing labour costs, increasing output and eliminating manual handling concerns.

Explore this section to find out more about the how TQC can help you with your factory assembly automation processes

- Assembly Automation

- Pallet Transfer Systems

- Rotary Systems

- Assembly Benches

- Robotics and Handling

- Checking Jigs & Assembly Fixtures

- Case Studies

- Casting Multi-Position Screwdriving & Marking System

- Co-operating Robots

- Pallet Assembly System for Automotive Glovebox Latch

- Pallet Assembly System for Metal Pressed Parts

- Laser Marking & Verification System

- Lead Pot Robotic Handling System

- Automotive Plug Feed & Check System

- Poka Yoke Assembly Bench for Automotive Latch

- Bearing Automatic Heat, Press & Assembly System

- Hot Insert, Cold Insert & Seal Assembly/Check System

- Robotic Handling & Leak Test Cell

- Robotic Weld & Fabrication System

- SCARA Robot cell for Automatic Assembly of a Small Electrical Handset

- Semi-Automatic Assembly System for Automotive Radiators

- Cylinder Head Cover Clean, Assemble and Test Suite

- Automotive Hinge Assembly & Test System

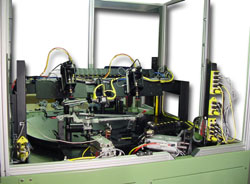

TQC have designed and produced a number of sophisticated rotary assembly and test projects for several demanding applications.

Rotary assembly machines (sometime knows as rotary tables or indexing systems) incorporate location tooling for the parts that is captive to a dial plate and individual stations that incorporate technology modules such as part feeding, robots, vision measurement to automatically carry out sequential operations.The advantages of using an indexing or continuous motion dial plate with a series of fixtures are the relative low cost and rapid index of the transport system. Fully automatic systems can reach throughputs of 400 a minute or more when continuous motion is used.

The part or parts of the assembly are basically indexed around a system until the required operations have been completed. Finished parts are generally unloaded onto a conveyor system for manual handling or automatically packed.

Rotary Assembly Machine by TQC

The use of a rotary assembly and test machine is advantageous when the cycle time is greater than 5 seconds and an operator is best used for some of the assembly processes.

For a fully automatic system, part feeding and handling can be integrated or for semi-automatic operation an operator can be used to position difficult to feed parts into the fixtures or used as a final inspection operation, or both. Rotary or carousel type assembly machines also offer a compact form of semi automatic machine.

The nest tooling tends to be “dumb” because of the continuous rotation. The assembly and test tooling is usually arranged in a radial fashion secured outside of the dial plate.

Twin or even multiple track nests are possible, as are interchangeable nests for different variants.

TQC have considerable experience in engineering rotary assembly machines, combining sophisticated test and assembly on the same machine.

Details from a recent rotary system machines installed by TQC for leading automotive clients

The business cases that are addressed by installing a rotary system into your production facility are that operations can be carried out fully automatically with the system producing complete products so there is no work in progress (WIP) produced during normal running. There is the flexibility of changing the tooling to accomodate new variants.

A rotary assembly system is a solution that can replace some or all manual labour allowing production running costs to be reduced. Further benefits are that operations can be quality assured and checked automatically this being pertinent to many production environments including the pharma and medical sectors, the automotive sectors and aerospace and defence industries.

To find out more about how we can help you with your automated assembly, robotic or special handling systems:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561