Assembly Automation: Jigs & Fixtures - Intelligent fixtures and fixturing

Explore the Assembly Automation Section

Automatic assembly machines and automation system solutions provide the best method for reducing labour costs, increasing output and eliminating manual handling concerns.

Explore this section to find out more about the how TQC can help you with your factory assembly automation processes

- Assembly Automation

- Pallet Transfer Systems

- Rotary Systems

- Assembly Benches

- Robotics and Handling

- Checking Jigs & Assembly Fixtures

- Case Studies

- Casting Multi-Position Screwdriving & Marking System

- Co-operating Robots

- Pallet Assembly System for Automotive Glovebox Latch

- Pallet Assembly System for Metal Pressed Parts

- Laser Marking & Verification System

- Lead Pot Robotic Handling System

- Automotive Plug Feed & Check System

- Poka Yoke Assembly Bench for Automotive Latch

- Bearing Automatic Heat, Press & Assembly System

- Hot Insert, Cold Insert & Seal Assembly/Check System

- Robotic Handling & Leak Test Cell

- Robotic Weld & Fabrication System

- SCARA Robot cell for Automatic Assembly of a Small Electrical Handset

- Semi-Automatic Assembly System for Automotive Radiators

- Cylinder Head Cover Clean, Assemble and Test Suite

- Automotive Hinge Assembly & Test System

TQC have designed and produced a number of jigs and fixtures for several applications across a number of industry sectors including the automotive, automotive plastics, welding and aerospace industries.

A current growth area in manufacturing is for intelligent fixturing. An intelligent fixture combines the mechanical location fixture with the intelligence of an automated PLC controlled system and the flexibility and dexterity of a human to provide a safe and quality assured method for assembly.

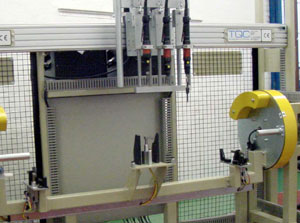

Detail from an intelligent fixture produced

by TQC for an automotive plastics client

Production logic has changed from batch production using dedicated techology to Just-in-Time (JIT) or sequenced production, with increased range of options or variants. This change means that suppliers need to produce the increased number of variations of the part as required without producing stock. Lower volumes of each part are now required with the increased number of variations. This means that full automation is not normally justifiable, so production is best suited to using the flexibility of a human operator with the 100% quality assurance of correct assembly provided by the intelligent fixturing.

Intelligent fixtures enable 100% checking

of assembly operations

Intelligent fixtures and fixturing provides the answer by allowing the part specific data to be input into the fixture (eg. barcode scanning) and then the operator can have a sequence of build or assembly displayed. This assembly or production sequence would be monitored and the release of the finished product would only be possible if the correct parts have been assembled.

Typical applications of TQC intelligent fixtures and fixturing:

- Poka Yoke Part Sensing

- Intelligent screwdrivers - torque, angle, screw count, fastener position monitoring etc

- Intelligent drilling

- Correct assembly checking

- Peg / Clip Insertion detection

- Length detection

- Intelligent visual monitoring - camera / colour sensing

- Electrical checks

- Automatic part locking on failure

- Part Marking or pass stamping

Assembly fixture with automatic screwdriver

with position monitoring

TQC also design and manucture the technology that sits either side of intelligent fixturing, jigs and fixtures and fully automatic assembly and test equipment. It is this experience across the range of technology that allows the correct solution to be provided for the customer for their production requirements.

To find out more about how we can help you with your jigs and fixture and intelligent fixturing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561