Leak Testing Case Study: Twin Station Leak Test Machine for Oil Sumps

Explore the Leak Testing Section

Leak Testing is used to ensure quality, tested and proven parts are supplied into the market. The use of leak testing equipment eliminates failures in the field.

Explore this section to find out more about the how TQC can help you with your leak testing requirements

- Overview

- Air Decay

- Helium

- Other Test Methods

- Leak Testing Services

- Standard Equipment

- Case Studies

- Automotive Brake Leak and Flow Testing

- Automotive Bedplate Leak Test Machine

- Battery Tray Leak Test Machine

- Chilled Beam Leak Test

- Flexible Leak Test Facility

- Fuel Tank Leak Testing

- Helium Leak Test Bench

- Helium Leak Testing of Automotive Fuel Pipes

- High Pressure Audit Leak Testing System with Datalogging

- High Speed Leak Testing of Pipe Fittings using Air and Helium

- High Speed Leak Testing of Plastic Vial for the Medical Industry

- Leak Test Facility for Water Valves

- Leak Test Cell with Robotic Handling

- Casting Leak Testing of Engine Blocks

- Medical Filter Leak Test Machine

- Medical Showerhead Leak Test Machine

- Plastic Fuel Rail Leak and Burst Test Machine

- Plastic Sump Pipe Leak Test and Assembly

- Small Medical Device Leak Test Machine

- Twin Station Leak Test Machine for Oils Sumps

- V6 Cylinder Head Leak Test Machine

- V6 Engine Leak Test Machine

- V8 Cylinder Head Leak Test Machine

- V8 Engine Block Leak Test Machine

- Valve Block Leak Test Machine

- Vauxhall Leak Test Machine

- Weapon Leak Test Machine

Client: Leading 2nd Tier Automotive Supplier

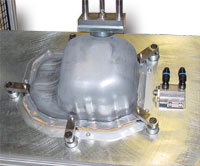

Part: Oil Sump

Machine supplied: Leak Testing Bench with Twin Stations

Overview: This system was designed and manufactured in order to give the customer the ability to leak test oil sumps within their production environment. TQC developed this system alongside the client to allow them to supply qaulity, tested parts to their customers.

Download details of this system as a PDF

To increase throughput, a twin station machine is available allowing a single operator to work alternately between the two fixtures, or two operators working independently on each fixture.

The Series 40 Twin Station machine incorporates a Nolek S9 leak test instrument which allows a dedicated leak test valve module per test fixture with a single panel mounted display unit.

This machine is for testing of pressed steel oil sumps which were tested by a single operator at a rate in excess of 1 every 30 seconds. The fully automatic sealing fixtures include a pass marker unit. The leak test was performed at a differential pressure of 1 bar with maximum leak rate of 200mm3/sec.

The unit incorporates:

- Standard aluminium extrusion bench

- Universal fixture areas

- Light guard access to each station

- Fully automatic sealing fixture

- PLC control system

- Built in Leak Test Instrument

- Standard operator interface panel

- Suitable for medium to high volume applications

To find out more about how we can help you with your leak testing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines experience to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561