Leak Testing Case Studies: Casting Leak Testing of Engine Blocks

Explore the Leak Testing Section

Leak Testing is used to ensure quality, tested and proven parts are supplied into the market. The use of leak testing equipment eliminates failures in the field.

Explore this section to find out more about the how TQC can help you with your leak testing requirements

- Overview

- Air Decay

- Helium

- Other Test Methods

- Leak Testing Services

- Standard Equipment

- Case Studies

- Automotive Brake Leak and Flow Testing

- Automotive Bedplate Leak Test Machine

- Battery Tray Leak Test Machine

- Chilled Beam Leak Test

- Flexible Leak Test Facility

- Fuel Tank Leak Testing

- Helium Leak Test Bench

- Helium Leak Testing of Automotive Fuel Pipes

- High Pressure Audit Leak Testing System with Datalogging

- High Speed Leak Testing of Pipe Fittings using Air and Helium

- High Speed Leak Testing of Plastic Vial for the Medical Industry

- Leak Test Facility for Water Valves

- Leak Test Cell with Robotic Handling

- Casting Leak Testing of Engine Blocks

- Medical Filter Leak Test Machine

- Medical Showerhead Leak Test Machine

- Plastic Fuel Rail Leak and Burst Test Machine

- Plastic Sump Pipe Leak Test and Assembly

- Small Medical Device Leak Test Machine

- Twin Station Leak Test Machine for Oils Sumps

- V6 Cylinder Head Leak Test Machine

- V6 Engine Leak Test Machine

- V8 Cylinder Head Leak Test Machine

- V8 Engine Block Leak Test Machine

- Valve Block Leak Test Machine

- Vauxhall Leak Test Machine

- Weapon Leak Test Machine

Clients: Tier 1 Automotive Engine Manufacturers

Parts: Automotive engine blocks

Machine supplied: Automatic casting leak testers for engine blocks

Overview: These systems were designed and manufactured in order to give the customer the ability to fully automaticaly test the water jacket and oil galleries within engine blocks on an automatic assembly line within their production environment. TQC developed this system alongside the client to allow them to quality assure that their engine blocks were leak free.

Download details of this system as a PDF

TQC have produced a number of leak test systems for a variety of automotive parts, this includes equipment for the testing of engine block castings.

The machines supplied to date for a range of automotive clients include manual and automated loading / unloading, multi cavity leak testing functions and system diagnostics.

TQC incorporates standard concepts and customises the equipment to suit the components and test parameters. Examples of components tested include the Vauxhall V6 engine, Rover K Series, Jaguar, Scania etc.

Features, Tests & Functions

- Ferrous and non ferrous castings

- Machined and 'As Cast' conditions

- Main cavity, High Pressure Oil & Water Cavity leak tests

- Interstream leak testing

- Integrated water submersal for leak area location

- Integrated flow & blockage testing

- Automatic core and ball plugging

- Nolek S9 multi-channel leak test unit allows up to 5 cavities to be tested simultaneously

- Manual loading and unloading

- Conveyor transfer

- Integrated robot cells

- Secondary machining operations

- Data logging of results with serial number pass marking for traceability

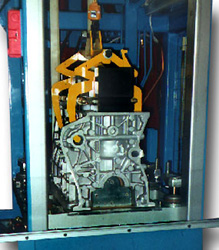

Cast Iron - fully automated V8 cylinder

block - automatic linear transfer

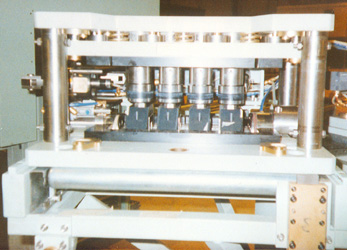

Interchangeable tooling

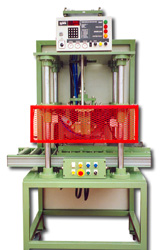

Cast Iron - 'As Cast' 3 cylinder

engine block. Fully automatic transfer.

Aluminium fully machined 6 cylinder

engine block with water dunk.

Manual load / unload with gripper 'lift assist'

Typical Leak Rates and Test Pressures for no-fluid leakage

- Oil Circuits: 50mm3/sec @ 0.3 bar 3cc / min

- Water Circuits: 200mm3/sec @ 1 bar 12cc / min

- Interstream: 140mm3/sec @ 0.7 bar differential 8.4cc/min

To find out more about how we can help you with your leak testing of automotive parts, including complex engine block casting leak tests:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines experience to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561