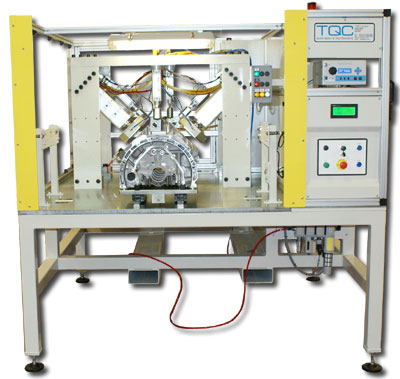

Leak Testing: Series 40 Standard Leak Testing Fixture

Explore the Leak Testing Section

Leak Testing is used to ensure quality, tested and proven parts are supplied into the market. The use of leak testing equipment eliminates failures in the field.

Explore this section to find out more about the how TQC can help you with your leak testing requirements

- Overview

- Air Decay

- Helium

- Other Test Methods

- Leak Testing Services

- Standard Equipment

- Case Studies

- Automotive Brake Leak and Flow Testing

- Automotive Bedplate Leak Test Machine

- Battery Tray Leak Test Machine

- Chilled Beam Leak Test

- Flexible Leak Test Facility

- Fuel Tank Leak Testing

- Helium Leak Test Bench

- Helium Leak Testing of Automotive Fuel Pipes

- High Pressure Audit Leak Testing System with Datalogging

- High Speed Leak Testing of Pipe Fittings using Air and Helium

- High Speed Leak Testing of Plastic Vial for the Medical Industry

- Leak Test Facility for Water Valves

- Leak Test Cell with Robotic Handling

- Casting Leak Testing of Engine Blocks

- Medical Filter Leak Test Machine

- Medical Showerhead Leak Test Machine

- Plastic Fuel Rail Leak and Burst Test Machine

- Plastic Sump Pipe Leak Test and Assembly

- Small Medical Device Leak Test Machine

- Twin Station Leak Test Machine for Oils Sumps

- V6 Cylinder Head Leak Test Machine

- V6 Engine Leak Test Machine

- V8 Cylinder Head Leak Test Machine

- V8 Engine Block Leak Test Machine

- Valve Block Leak Test Machine

- Vauxhall Leak Test Machine

- Weapon Leak Test Machine

TQC have recently developed a series of standard leak test benches. The Series 40 bench is a low cost, standard leak testing bench with integral plc control, capable of housing any Leak Test Instrument.

The Series 40 standard leak test benches can combine automatic assembly with leak testing operations. This allows for compact, space and time efficient solutions to be provided for higher throughput production.

Typical applications when combining operations into a single machine include -

- A series of different leak tests carried out on different cavities at varying test pressure and leak limits

- A press process or ball insertion followed by a leak testing and marking of the tested part

- A screwing or glueing operation following by leak testing

The units typically incorporate:

- Standard aluminium extrusion bench or fabricated and welding box section frame

- Universal fixture area with option front load/unload position and shuttle to test area

- Light guard, sliding or self guarding

- Fully automatic sealing fixture

- PLC control system

- Adjustable feet and Forklift Truck access or castors for more flexible location

- Built in Leak Test Instrument

- Standard operator interface panel

- Suitable for medium to high volume applications

This unit is configurable for either over-pressure, vacuum or dosing applications.

For a printer friendly copy of the information on this page

To find out more about how we can help you with your leak testing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines experience to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561