Special Machines: Plastic punching and degating equipment

Explore the Special Machines Section

Special Machines and custom built equipment provide the best method for solving those bespoke requirements which include assembly, handling and testing disciplines.

Explore this section to find out more about the how TQC can help you with your special machines and custom, bespoke machine requirements

- Special Machines

- Test Machine Equipment

- Plastic Processing

- Feasibility Studies / Proof of Principal / Prototyping

- Case Studies

- Turbocharger Testing

- Clutch Testing

- Plastic Bumper Punch Machines

- Plastic Bumper Assembly and Checking Fixtures

- Plastic Bumper Painting & Polishing Fixtures

- Rear Bumper Handling, Assembly and Pressing

- Front Bumper Assembly and Pressing

- Mechanical Handling - Dynamic Buffer Conveyor

- Platen Based Flow Testing of Turbocharger Housings

- Gas Supply and Monitoring System

TQC has supplied a large range of plastc punching and degating equipment predominatley to the automotive plastics industry. The equipment uses modular design and proven technology modules to fullfil the customers requirements. TQC has engineered machines to punch holes and features in painted and lacquered parts without crazing the painted / lacquered surface.

Examples of equipment supplied is shown below and within our case studies

This machine accurately removes the fan gate from a large body moulding. Since the cut line is visible on this external body part, we remove the fan gate, leaving an excellent surface finish, without marking the 'A' surface. Although supplied for hand loading, the machine was designed to be upgraded to interface with a press robot. The machine uses a hydro-pneumatic 3-part punch system and is suitable for use by an unskilled operator

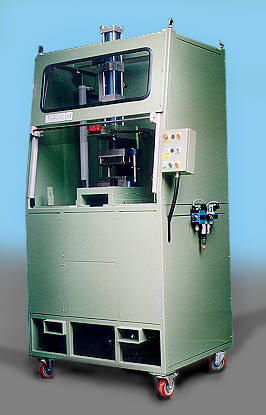

The picture opposite shows a machine to accurately punch shaped holes into painted and unpainted moulded plastic bumpers, allowing the use of the same bumper on different models of vehicle. Bumpers are manually loaded and unloaded, through a light guard. The entire automatic cycle is complete with 15 seconds leaving a perfect finish on all bumpers. Waste material is collected via chutes, which feed into bins outside the guarded areas. The punches are actuated hydraulically with independent adjustable punching loads and speeds

The picture opposite shows a machine to accurately punch shaped holes into painted and unpainted moulded plastic bumpers, allowing the use of the same bumper on different models of vehicle. Bumpers are manually loaded and unloaded, through a light guard. The entire automatic cycle is complete with 15 seconds leaving a perfect finish on all bumpers. Waste material is collected via chutes, which feed into bins outside the guarded areas. The punches are actuated hydraulically with independent adjustable punching loads and speeds

TQC have also supplied a machine that is designed to remove a portion of an engine cover, to allow for build variation. A large and complex cut path is accommodated. An excellent finish to the cut and to the 'A' face is achieved to reach the standards required for this top quality vehicle. This machine has been designed generically to adapt to the requirements of a new part design.

Customer Benefits of using TQC Punching and Degating equipment include –

- Improved product quality

- Reduced operation time

- Reduced costs

- Increased turnaround

- Operator safety

- Automatic collection of waste material

- Complete technical documentation

- Operator and service manuals

- Full training

- Service back-up and warranty

- CE Marking

- Poka Yoke Verification

To find out more about how we can help you with your special machine and plastic punching requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561