Special Machines Case Studies: Platen-based flow testing of turbocharger housings

Explore the Special Machines Section

Special Machines and custom built equipment provide the best method for solving those bespoke requirements which include assembly, handling and testing disciplines.

Explore this section to find out more about the how TQC can help you with your special machines and custom, bespoke machine requirements

- Special Machines

- Test Machine Equipment

- Plastic Processing

- Feasibility Studies / Proof of Principal / Prototyping

- Case Studies

- Turbocharger Testing

- Clutch Testing

- Plastic Bumper Punch Machines

- Plastic Bumper Assembly and Checking Fixtures

- Plastic Bumper Painting & Polishing Fixtures

- Rear Bumper Handling, Assembly and Pressing

- Front Bumper Assembly and Pressing

- Mechanical Handling - Dynamic Buffer Conveyor

- Platen Based Flow Testing of Turbocharger Housings

- Gas Supply and Monitoring System

Client: UK Based Engineering Company

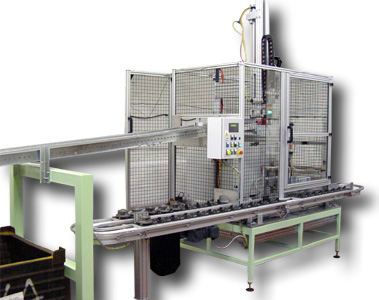

Machinery supplied: Platen Based Flow Testing of Turbocharger Housings

Overview: This equipment has been designed and manufactured in order to give the customer the ability to 100% check a turbocharger housing was correct and allowed sufficient flow to pass through. TQC developed this equipment alongside the client to ensure that they supplied correct parts to their customer, a leading automotive vehicle manufacturer.

Download details of this equipment as a PDF Page 1

Key features:

- Flexlink conveyor & platen part transfer system

- Flow test station using a rotameter and digital display with minimum flow alarm trip point

- Impact marking of passed parts

- Automatic unload

- 30 second cycle time, 10 minute infeed buffer

The customer required a 100% production flow test for the water cavity with a turbocharger centre housing casting to ensure sufficient flow passes through.

The customer required a 100% production flow test for the water cavity with a turbocharger centre housing casting to ensure sufficient flow passes through.

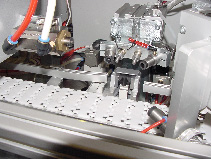

The flow test uses an air flow correlated to a minimum water flow value at a pressure drop of 0.1bar. The test checks for total or partial blockage of the water cooling cavity.

This TQC system allows manual loading of parts into an infeed buffer and then automatic flow testing of the parts.

At the test station the part is lifted clear of the platen, the open ports are sealed and air is used as the test medium. The air flow is measured and if sufficient flow is achieved, the part is marked as a pass.

All parts are automatically unloaded by a 2-axis pick and place system, passed parts into one lane, failed parts into another. The empty platens are recirculated ready for manual re-loading.

All parts are automatically unloaded by a 2-axis pick and place system, passed parts into one lane, failed parts into another. The empty platens are recirculated ready for manual re-loading.

TQC can also other platen based system and can supply test equipment for a variety of requirements.

To find out more about how we can help you with your special machine and flow testing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561