Leak Testing: MALT Leak Test Instrument MALT 501

Explore the Leak Testing Section

Leak Testing is used to ensure quality, tested and proven parts are supplied into the market. The use of leak testing equipment eliminates failures in the field.

Explore this section to find out more about the how TQC can help you with your leak testing requirements

- Overview

- Air Decay

- Helium

- Other Test Methods

- Leak Testing Services

- Standard Equipment

- Case Studies

- Automotive Brake Leak and Flow Testing

- Automotive Bedplate Leak Test Machine

- Battery Tray Leak Test Machine

- Chilled Beam Leak Test

- Flexible Leak Test Facility

- Fuel Tank Leak Testing

- Helium Leak Test Bench

- Helium Leak Testing of Automotive Fuel Pipes

- High Pressure Audit Leak Testing System with Datalogging

- High Speed Leak Testing of Pipe Fittings using Air and Helium

- High Speed Leak Testing of Plastic Vial for the Medical Industry

- Leak Test Facility for Water Valves

- Leak Test Cell with Robotic Handling

- Casting Leak Testing of Engine Blocks

- Medical Filter Leak Test Machine

- Medical Showerhead Leak Test Machine

- Plastic Fuel Rail Leak and Burst Test Machine

- Plastic Sump Pipe Leak Test and Assembly

- Small Medical Device Leak Test Machine

- Twin Station Leak Test Machine for Oils Sumps

- V6 Cylinder Head Leak Test Machine

- V6 Engine Leak Test Machine

- V8 Cylinder Head Leak Test Machine

- V8 Engine Block Leak Test Machine

- Valve Block Leak Test Machine

- Vauxhall Leak Test Machine

- Weapon Leak Test Machine

Technical Data

|

Specification |

Pressure range |

-0.5 bar to 3 bar |

Pressure resolution |

0.1 Pa |

Measurement methods |

Differential pressure decay |

Setup / Configuration |

Web interface via Ethernet or wireless device (option) |

Leak test programs |

16 supported within the instrument with more available via file import functions |

Data collection |

On board SD Card for with FTP download facility, all data stored in day files with date and time stamp |

Communication ports |

1 x RS232 |

Power requirements |

24v DC, optional 220/110VAC power supply unit |

Air supply |

Maximum 3 bar clean dry air |

Dimensions |

25x9x17cm |

Weight |

1kg |

Enclosure rating |

Up to IP54 |

Options |

Calibration unit |

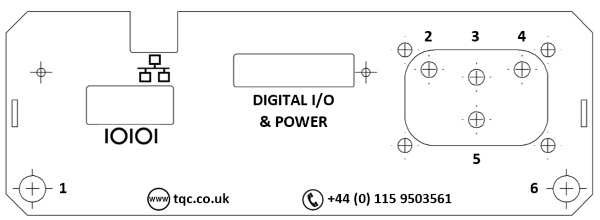

Rear Panel Connections

1 – AIR SUPPLY TO E2P (IF E2P FITTED)

2 – CALIBRATED LEAK

3 – VENT

4 – TEST

5 – TEST PRESSURE

6 – E2P OUTPUT (IF E2P FITTED)

For a printer friendly copy of the information on this page

To find out more about how we can help you with your leak testing requirements:

We build all machines in-house, applying our 25+ years experience in specialised test and automated handling machines experience to the engineering projects we undertake. We offer customer support, backup and service call-out for all projects, whatever the size.

Get in touch with us to discuss your requirements and we will be happy to offer our professional advice and visit you at your site.

- Contact us online

- Email us or call us on 0115 950 3561